I’m always on the lookout for new material to use for my products. After all, it was a high-end ski jacket I saw in Japan which led me to Soft Shell. The more I learn about modern materials, I realize that many of the key breakthroughs these days are achieved by combining existing materials in unique ways, rather than creating something that never existed before. That was the approach taken with Composite Laminate.

Tyvek itself is a type of sheet plastic which achieves its incredible strength to weight ratio by being constructed from interlocking strands arranged in random patterns. It starts off as white and the colors are achieved by printing on them. Over time, they sort of wear in like jeans so don’t stay looking new as long as Soft Shell wallets, which are dyed. But what if we could add an additional layer of flat plastic on top of the Tyvek to trap in the color while providing a more abrasion resistant surface?

The concept of adding another layer was the easy part. The first challenge was that some of the best processes for permanently connecting materials are heat activated. The only problem? Tyvek has a low melt point and pretty much hates getting hot. The equivalent of putting sand in a gas tank is to feed some Tyvek into a laser printer! To overcome this, I worked closely with an experienced local shop to experiment with different techniques until we found one which would join them.

The secret was to not only experiment with the temperatures, but also the speeds at which the material was run through the machine. It turns out that you can “break the rules” for melting Tyvek, but only for a fraction of a second… so we feed it through the machine at a fast enough rate so we get adhesion without letting the Tyvek turn into a rippled mess.

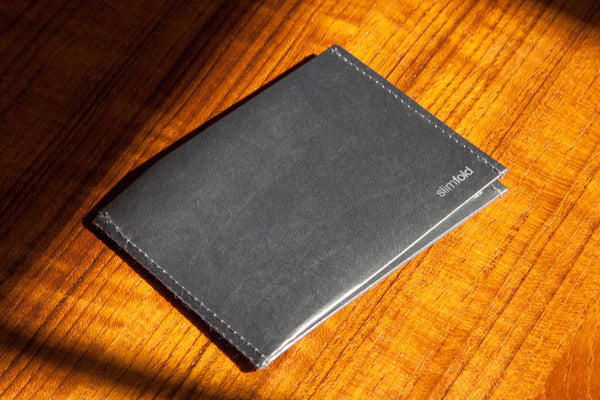

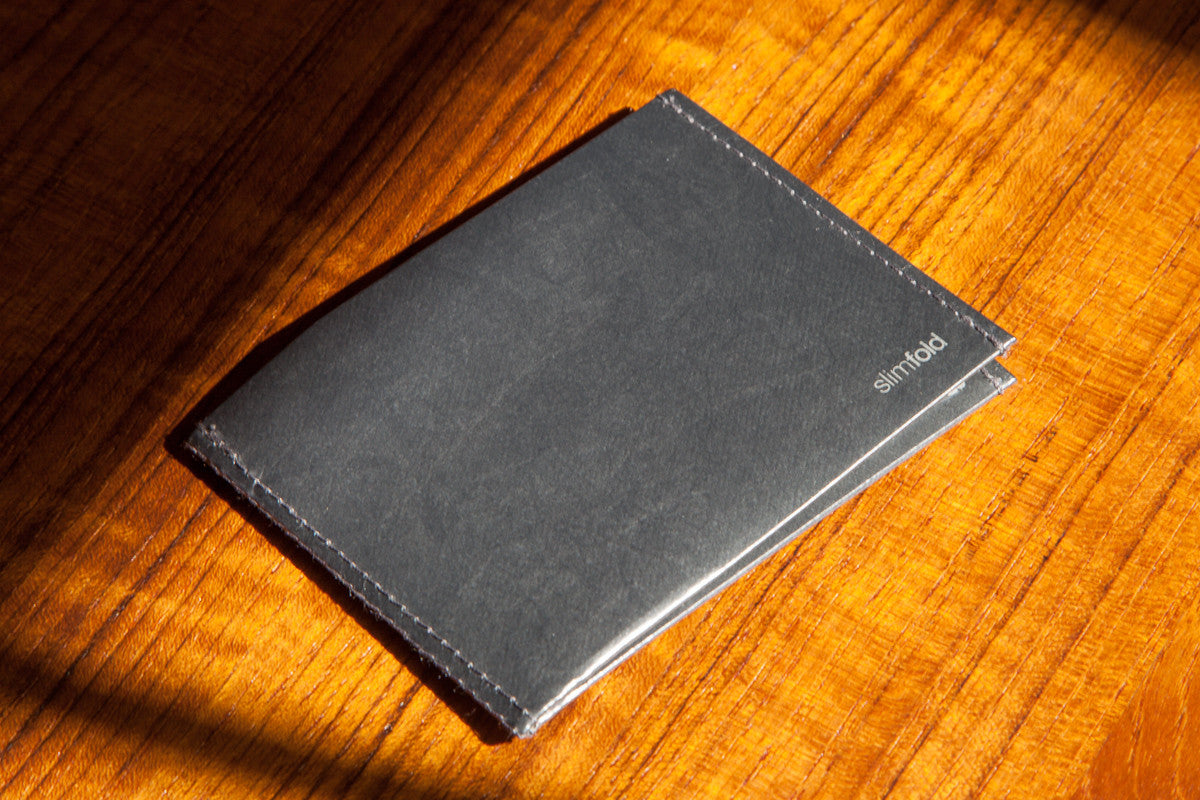

The second challenge was to select the right material. There’s a vast array of colors and finishes so even narrowing things down to just the clear ones still left many options. In the first test, we used a glossy one and the wallets came out looking like patent leather shoes! We ended up special ordering the most matte finish material available, which was just released by the supplier. Even though the Tyvek beneath it is a deep black, when covered by this material the light behaves in a really interesting way which causes it to appear like a deep matte gray. You can still see the swirls of the Tyvek material underneath which is pretty cool. I’m calling this color “carbon” to convey the ultra matte effect achieved by the combination of both color and material.

How Thick is The New Laminate Wallet?

When completed into a wallet, it’s just barely thicker than a normal Tyvek model. Its capacity is also slightly less… holding up to about 6 cards depending on how many bills. It’s probably good for folks who are already pretty minimal and just looking for something which stays looking new longer and is still ultra-thin.

Since this is a new combination of materials, I’m introducing it as a Beta at first… only producing a certain number and selling them for the cost of the existing Tyvek wallets even though the cost to make them is significantly more. I hope you’ll give one a try and let me know how you like it!

Hey Dave! just wanted to let you know that I had bought one of these beta production runs and wanted to let you know that I really liked this model for its durability and shiny look.

But it does come at the expense of a little less room and tighter for those who may be filling their wallets to the brim.

For me it was just right! Thanks for the great work!