If printing on Tyvek were easy, I probably wouldn’t have a company. Not because of the competition of everyone doing it, but because I would have been able to make just a few wallets in the beginning.

Since the material is essentially a sheet plastic, it’s really hard to even put ink down on it and get it to adhere at all. Special commercial presses are required so right away you’ve got to print many thousands of them even if you want just one.

To get the printing quality I wanted, I had to produce so many that it made sense to sell the extra ones... so SlimFold got it's start.

Process

The process of printing on Tyvek actually has a lot of variables. First, there’s the type of Tyvek to choose. It comes in a fabric style, which is what clean room “bunny suits” are made of, and also a paper style used for FedEx mailing envelopes. I use the paper-like one but even then, you can get a variety of thicknesses, coatings, and even textures.

Next is the ink. This is one of the keys since they have different properties. The ones that will stick to Tyvek at all can only be applied with a commercial press. In addition to adhering to the Tyvek material, it also needs to resist the abrasion of taking it in and out of the pocket.

Finally is the press itself. Some inks and processes can only be achieved with specialized equipment. Just like laser printers and ink jets, the ink and the printer needed to apply them are completely different.

The issue

One thing that’s very difficult to account for is how things will wear over time. This is especially true of things which whose wear patterns differ from customer to customer. Let me ask you a question: How long do jeans last? Well, although denim is very durable and stays functional for a very long time, it may not stay looking new for it’s entire serviceable lifetime. So you may need to buy new "work jeans" fairly frequently if you work in an office. But if you work in construction, it may not matter how they look but because of how hard you use them, you still may need to replace them more often.

Similarly, Tyvek wears in over time and looks less new. Most of the time, folks are amazed by how long their wallets last and we’ve got tons of repeat buyers who get fresh ones once their old one no longer looks new enough. But then we had several folks reach out who weren’t happy with how the printing wore. As you can imagine, this was extremely difficult to troubleshoot. How were each of the people using it? How many cards did they have? And if something wasn't right with the printing, how can we even tell which print run their wallet came from?

Solution

Luckily, it was the feedback from customers which ultimately helped us figure out what was going on. The first trend we noticed was that it only seemed to only affect black wallets. With all the variables involved, could the ink color also be one? Or was that just a function of the fact that it’s the one we sell the most number of?

My approach to creating products is to put in the hard work of designing it right in the beginning, partner with local vendors to fine tune production, and add a product to my line. When I’m getting close to running out of stock, I go back to those same vendors to produce more. When I talked to the printer, it turned out they had modified their press just before my most recent run. This should have theoretically improved things, but the new press modification also used a new ink. They said there are a variety of black inks available from different manufacturers, each with slightly different properties depending on their formulation. As discussed in this post, there isn’t really a way to “proof” things on Tyvek to make a test print. So how could I know which was the best to use?

To test them, we essentially had to do a mini print run using all of the different blacks on one sheet.

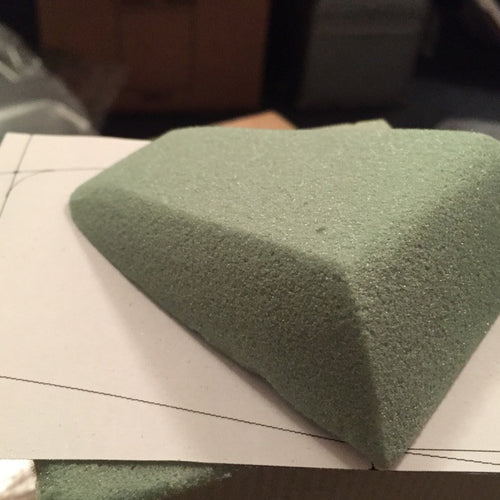

After the print run was done, I devised an abrasion test: a 320 grit fine sandpaper attached to a cylinder with a specific weight. I then dragged it parallel to the surface, allowing only the force from the weight of the cylinder to transfer to the surface. Okay, that’s a fancy way of saying I taped some sandpaper to a roll of duct tape, but it was a little scientific, ok?

It let me see what the wear was at 10, 20, then 40 rubs… and then compare that to another sample print. While this wouldn’t give us an absolute measure of abrasion resistance, it was good enough to show which printing method was best. I also compared it to sample press sheets from each of the previous 7 print runs we’ve done. Interestingly, this also confirmed the trend of previous print runs being better and the latest one not being quite as good.

Just to be sure, we then also sent all of the print samples to DuPont, the manufacturer of Tyvek, where they had a sophisticated abrasion testing machine. The lab results matched what I had found with my simple sandpaper test so we had a winner.

Conclusion

Ok, you may be asking yourself, “Why even go though all this trouble of printing on Tyvek at all?” I began asking myself the same thing and so released the white version… the color natural Tyvek starts out as.

Or why not make wallets from something that stays looking new for longer? How about custom making a material that stays looking new for years, outlasts leather, and is still super thin? No worries- I’m on it.

Thanks to all the customers who provided images of their wearing patterns and several who even sent theirs back to us for inspection. There were a few repeat customers whose feedback was especially valuable because we could look back in time to see what their first one looked like compared to the more recent ones. They essentially provided data for a “within” subjects study with more powerful insights from just a few people. The richness of those information from those customers was ultimately what led us down the right path.

This is a reminder that making products isn’t always a steady upward path of progress… even when you’re just trying to make more of something that was previously produced.

0 Comments