Over the past month or so I’ve been working on a mask in the background. But I’ve decided not to pursue the project… so I thought I’d share a bit about the design process that went into it as well as the reasons which contributed to my decision to set it aside.

First some context- As this whole epidemic unfolded, I followed along like everyone else about the shifting guidelines around mask use and the shortage of Personal Protective Equipment (PPE) for healthcare workers.

At first I thought I could make something for medical workers since 3M N95s were in short supply. But it quickly became evident that they would need millions of masks… and there were strict requirements around which ones were approved.

Meanwhile, the strategy was emerging to provide medical staff with washable cloth masks which they could wear over their N95s to extend their life. And an extraordinary grassroots effort sprung up for volunteers to sew masks at home to donate. At that time, the guidance from the CDC was still that the general public didn’t need to wear masks, but skepticism of that guidance was also growing.

A driver for the recommendation was clearly to avoid a run on 3M N95 masks and looser fitting surgical masks. But many people were beginning to ask- why wouldn’t it be a good idea for the general public to wear them? The insight was also developing that the purpose of the masks for the public wan’t to keep dangerous stuff out, but to keep you from spreading the virus if you’re an unknown carrier.

With this context, my design approach shifted to come up with something for the general public that was comfortable, breathable, and washable. It should provide practical protection and solve some of the issues with other masks such as hurting the ears.

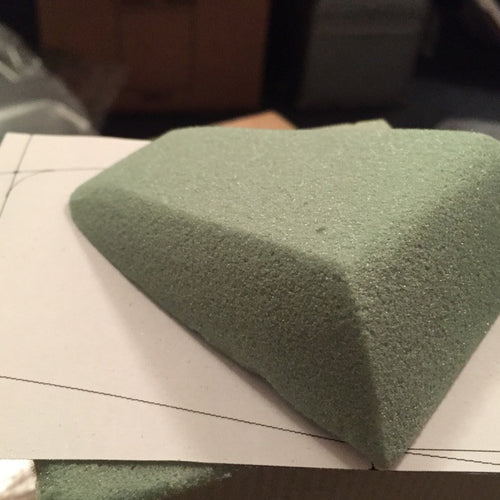

I was pretty happy with my initial prototypes… and the pattern came together quite nicely. The preliminary idea was to use performance fabrics and assemble it in a way similar to technical jackets- with bungee material and cordloc slides. I even cut apart a Nike shirt of mine to work with a fabric with the right feel. Refinement and production met some major hurdles though...

Challenges

First, my prototyping ability was quite hampered by not having access to my studio and industrial sewing machine. It made my realize how efficient having more space and the right tools is!

Another limiting factor was that it was difficult to get materials due to extended shipping times online. After all, if I used Soft Shell, you wouldn’t be able to breathe through the fabric so I had to order other kinds of cotton blends to try out.

Next was the fact that factories were operating at limited capacities… and mostly focused on PPE either for medical workers or consumers.

Lastly, I was finishing up fulfilling the Coin Kickstarter project. The product was being produced in Japan and they weren’t delayed at all.

While our backers are super supportive and would have certainly understood any delays given the circumstances, we had the opportunity to still complete the Kickstarter on time. So that remained the priority.

Once we shipped all of the rewards (a little early even!) I turned back to the mask project. By that time, the landscape had shifted once again…

The CDC did an about-face and fully recommended that the general public use a reusable fabric mask- essentially a DIY version of what I had been designing. But there was also a flood of them already on the market that were inexpensive and probably good enough for most folks. So many that the marketplace was pretty confusing and lots of companies were running expensive advertising campaigns and selling tens of thousands of them. You probably noticed your feeds blowing up with masks so the advertising and email platforms tried to counterbalance it. So much so that Google and Facebook started banning advertising for them and any email mentioning masks were going straight to spam.

I decided that if the rest of my development came together really smoothly and there was a path to production, I’d continue. But that if there were too many headwinds I’d stop.

I was able to source a fabric similar to my Nike shirt and the patterns came together so talked to a couple of factories I’ve worked with to check in. Overall, they had shifted to making some variety of PPE- some for donation to medical workers, others for profit to consumers, and everything in between. And it was very crowded.

With all of these things considered, I could see that the path ahead required more refinement of the product before I could arrive at something I was happy with. And then I’d have to elbow my way in to the factories to get any made. If I were able to make some, the marketplace was choppy and fraught.

My ultimate purpose was to create a way for the public to get masks while simultaneously helping to fund some of the medical and first responder PPE efforts going on. So when a friend connected me with the DIY MakeMasks2020 community I found I was still able to help them out with some sourcing and logistics as well as by donating directly. You can contribute directly to them here or stay tuned to our mailing list for other opportunities to help them out.

As I’ve mentioned before, Seth Goden’s The Dip has been hugely influential to me and served as a guide during this process. In it, he covers how to know whether you’re facing natural resistance in a project (a dip) that you should push past… or digging a hole. If you discover that you’re digging a hole it’s best to stop. Immediately. And move on.

On one hand it may seem like it would have been better not to spend any time on a mask project at all… or it may seem like it would have been better to push through and get a product out there. But the reality is that the exploration I did was just the tip of the iceberg of what would have been necessary to get the product ready for release. The purpose of this exploration phase was partly to come up with the design concept, but also to get an idea of what the scope of the rest of the project looked like.

Who knows- if the idea incubates for awhile, I may pick it back up. But for now I’m stepping away from producing my own and doing what I can to support the maker movement that’s grown up around creating DIY masks for medical workers and first responders.

What are your thoughts? Are you wearing a mask these days? Are you able to get your hands on one you like?

Had to make custom masks for myself because of my big head, nose, beard and futzy little glasses. Also wanted to get the look, function, and feel just right so mine have three layers for strong exterior and structure, a high thread count filter layer, and soft inner lining. Wire structure around the nose is critical to keep glasses from fogging.

There may be parts of the market for people like me with special needs, but the combination of DIY and mass produced cheap alternatives makes this market hard to enter profitably. Too bad the WHO and CDC were coming up with weird manipulative narratives instead of facing up to the task of protecting people when it would have made the most difference.

So cool that you worked on this, even if it didn’t work out. I bought your wallet last month for my ex (we’re good friends) for his 81st birthday. He went from carrying a big leather Coach wallet to carrying your super slim one, and he loves it! I was so excited to see him make this change. He said he no longer carries a lot of cash, since switching to the slim wallet, but we both agreed that’s a good thing, for a lot of reasons. So I just wanted to say thank you, from a boomer and an octagenarian who love your products. :)

@Ankit – Glad you like the design! Sorry the ones you got didn’t fit well. I’ll let you know if I end up making them someday.

@Peter – Cool, glad you like it! Hope the new ones you ordered from the other company work better than the last ones you got.

@Doug – Yes, if you’re a healthcare worker you can request a free 3D printed hook that goes behind your head to make masks more comfortable. Or let me know on the contact page and I’ll try to get you in touch. I’ll let you know if I come up with a minimalist mask at some point.

@Rene – Glad it’s helpful! Yeah it’s really hard to know when it’s right to stop… but I think recognizing that sometimes that is the right answer is important. If you never start, you’ll dream of everything magically falling into place. But if you work it out enough to see that your initial idea isn’t a slam dunk, that can be good to know too. But best to avoid going all the way down the path and then stopping!

Thanks for sharing this. It confirms for me that it’s ok to spend some time on a product idea that ultimately hits a dead end. Better to spend a little time up front than to spend far too much time down the line fighting an uphill battle.

Dave, I love your backpack and wallet. I use both currently. Please make a general public mask that doesn’t hook behind the ears. I can’t tell you how many health care workers who modify masks so they don’t cling from their ears or irritate their ears. I’d love it if you made a minimalist general use mask. Thank you for all your product development work.